Our modular delivery model has been refined through innovations, experience, and lessons learned, reaching back over five decades.

Our method is predictable, transparent, flexible and robust. Striving for optimum quality with a constant safety focus.

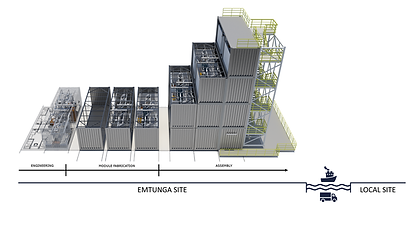

EMTUNGA Delivery Model

Flexible delivery – consistent deliveries

Our model suits irregardless of choice of delivery model keeping the same standardized process, tailored to fit your project.

ENGINEERING, PROCUREMENT,

MODULE FABRICATION AND ASSEMBLY

are carried out at Emtunga’s premises. The complete facility is shipped to final construction site for installation in one single lift.

-

Engineering and Procurement in close proximity to fabrication

-

Construction in tried and tested environment

-

Minimum disruption at final construction site

-

Shortest delivery time

BASED ON A STANDARDIZED AND WELL-PROVEN EXECUTION MODEL THE EMTUNGA MODULAR WAY

BRINGS YOUR PROJECT NUMEROUS ADVANTAGES DURING ALL PROJECT PHASES.

-

SHORTER TIME TO MARKET

-

COST AND SCHEDULE PREDICTABILITY

-

BETTER CASH FLOW — JUST-IN-TIME DESIGN, PROCUREMENT AND CONSTRUCTION

-

EASILY EXPANDABLE FACILITY

-

SIMPLIFIES COMPLEX DESIGNS

-

SAFE CONSTRUCTION — AT GROUND LEVEL

-

FLEXIBLE PRODUCTION SEQUENCING

-

INTEGRATION AND PRE-TESTING IN CONTROLLED WORKSHOP AREA — REDUCED RISK AT FINAL CONSTRUCTION SITE

-

LESS DISRUPTION AT FINAL CONSTRUCTION SITE

-

FLEXIBLE EXECUTION — BASED ON ONE STANDARDIZED AND SOLID PROJECT EXECUTION MODEL